"Mechanics": Keeping the Mustang combat-ready

Most articles concerning the P-51 Mustang, or any other aircraft, deal with the design process and combat record of the type, and don't mention most maintenance issues related to the aircraft. This is not only unfair to the "ground crews" as they were commonly called. Indeed, many aircraft with superb performance were plagued with maintenance problems which greatly limited their operational usefulness. Not considering this aspect when studying any airplane therefore tends to lead to a "biased" view. Hopefully, this article is meant to correct this problem. However, data on the subject is limited, and any help or corrections would be greatly appreciated.

|

| A rare WW2 color photograph of the flight line. |

Mechanics

What is a flight mechanic? Grossly, one could say that a mechanic is just one of the guys involved in keeping an airplane running. In practice, mechanics were enlisted men who had received formal training in different specialties: on any USAAF airbase in World War 2, one could find armourers, mechanics, crew chiefs and other specialists...

In Worl War 2, mechanics first completed basic military training and were then assigned for four months to a technical school where they would learn the basics in aircraft and engine maintenance and repair. There, they were taught different phases, such as fundamentals, structures, hydraulics, propellers, instruments, engines, electrical systems, fuel systems, engine operation, and tow phases of aircraft inspection.

After competion of this "A&E training" (aircraft and engine training), some of these men would go to an aircraft manufacturing plant where they were trained for a month by civilian instructors of the company. Out of these, some would receive even further instruction in specific fields such as propellers, engines, instruments and others to become specialists.

Out of these different training courses, men were then reassembled and sent to be part of a specific squadron to perform their duties in the "Engineering" section of the squadron, a term which has been abandoned since. On creation of a new squadron, mechanics were faced with a problem: pilot training generated a lot of flying, and maintenance duties were therefore very high, often continuing at night to support the squadron's activities.

Upon arrivals in England, mechanics assigned to Mustang-equipped units were often sent either to the Rolls-Royce company's engine plant in Derby or to the Burtonwood Air Depot for P-51 airframe school. At this point, the excessive work load experienced in the USA during training often paid off: having worked so hard with constant pressure, most mechanics were able to work very efficiently and establish a good maintenance record.

However, the cold and damp English weather made the job somewhat harder for those working in badly protected shelters. In addition, the job being to have as many aircraft available at any given time, a lot of aircraft maintenance was done at night with complete blackout in order, meaning that only minimal lighting was authorized. Long escort missions, which were the P-51's most common assignment, although meant that 25-, 50- and 100-hour inspections had to be carried very often. Combat damage was the final touch to the heavy workload the mechanics had to bear: mechanics specialized in sheet metal were always busy "patching" combat-damaged airplanes. The heavy workload was also a source of accidents. As Joseph Deshay, a 357th Fighter Group hangar chief, recalls: "We were trained for accident awareness and to take all precautions against possible fire hazards. A clean hangar and a tidy one was a must."

Equipment and tools were not available to the mechanics, but when that was the case, they made their own tools. If no material was available to make the necessary tools, then it was borrowed from somebody else, or sometimes stolen in a "moonlight requisition"!

Servicing the Mustang

Mechanics of fighter units equipped with Mustangs also discovered that the Merlin engine was assembled with Witworth thread nuts and bolts. Wrenches for this equipment were in short supply and many had to be built. The Mustangs were supposed to be delivered with the tools needed for maintenance on board, but these apparently often "disappeared" before their arrival at the squadron. However, imaginative welders often came up with useful equipment of their own design, replacing missing material or inventing something better.

|

| Mechanics servicing the Mustang's license-built Packard Merlin engine. |

Work started very early in the morning. Time to get up was sparse: anyone who took too long missed the truck ride and had to walk or bicycle to the flight line. When the day's mission was bomber escort, the waking mechanics could hear the bombers already taking off and assembling above them.

According to Merle Olmsted, another 357th FG mechanic, the P-51 was one the best US fighter of the time from a maintenance point of view, and had been designed as such. The P-38, which could have been the long-range fighter the USAAF desperately needed in 1943 and early 1944, was plagued with maintenance and mechanical problems and boasted the worst readiness of all three major US fighters in Europe at the time (P-38, P-47 and P-51). These problems were solved in the latest models of the Lightning, near the end of the war.The P-47 was probably on par with the P-51, but was too short-ranged to be much of an escort fighter.

But the P-51 had its weaknesses. One of them was the short life cycle of the engine plugs, which most often had to be changed after every mission, depending on the quality. Another was the coolant system. It was vulnerable to damage and often suffered leaks, often due to a change in temperature. Whenever a mechanic saw a pool of coolant liquid under the aircraft when arriving, it probably meant coolant liquid leak and therefore the engine cowling had to be taken off and the leak found before the pilot's arrival. Since it was difficult to distinguish coolant liquid from water, mechanics usually put their fingertip in the pool of liquid and put it to the tongue. If it had a bitter taste, it was the poisonous coolant liquid!

Another problem with the Mustang shows the mechanics' creativity. If a sharp turned was taken during taxiing, the tail wheel tire often rolled off the rim or simply blew. To resolve this problem, mechanics created or recuperated extra tail wheel units, and waited with a Cletrac crane next to the flight line. If a tailwheel tire blew, the crane lifted the aircraft's tail and a mechanic replaced the entire unit with a spare one. The operation took little time, and the pilot was soon able to take off and rejoin its flight.

|

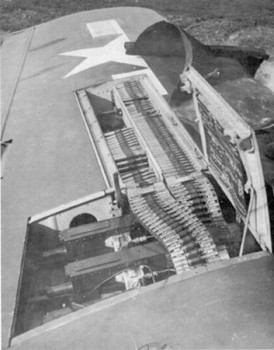

| A view of the Mustang's left wing ammo and gun bay. Note the upright position of the guns, indicating the aircraft is a P-51D or K. |

Armourers were probably happy with the P-51. Most of the training appears to have been made on P-39s or aircraft which required gun synchronization, so as not to have bullets hitting the propellers. The Mustang's four, or later six, .50 caliber M2 Browning machine guns did not fire through the propeller arc, and therefore they were dispensed with the troublesome synchronization work. In addition the M2 was a reliable weapon,

There was however one problem with the Mustang's guns. The P-51B/C model had four .50 caliber guns, with feeding mechanisms capable of pulling 35 pounds of ammo. This was plenty, but a problem appeared in combat: under heavy maneuvers, the weight of the ammo increased with g-forces, resulting in jams and stoppages. The fact that the guns were mounted in slanted position increased the problem, as the ammo belt had to go through a sharp 'kink' before entering the gun. Ground crews resolved the problem by using booster motors recuperated from B-26 gun turrets, providing the extra power that was needed. This apparently worked very well, as extra quantites of those B-26 parts were ordered to modify all B/C models. Only with the D model did North American resolve the problem on the assembly line, by totally redesigning the gun installation.

Another problem with the M2 guns was freezing at high altitude. Despite the fact that electrical heating was provided to stop the guns from freezing, the solenoids from the guns did freeze. Mechanics simply added "homemade" insulation to resolve the problem. Ammo belts were made with two armor piercing rounds, two incendiary rounds, and one tracer round, this pattern being repeated on the entire length of the belt. Subsequently, it was decided that the advantage of seeing where you were shooting was not worth the disadvantage of showing the enemy where you were shooting from, so tracers rounds were removed, except at the end of the ammo belt, in order to alert the pilot he was nearly out of ammo.

One last problem reported by mechanics is that in extended bursts, the gun barrels would overheat, and the rifling would erode, rendering the guns very inaccurate.

|

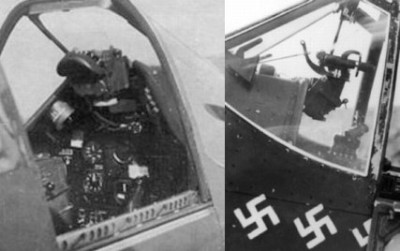

| The Mustang's gunsights: on the left is the K-14 computing gunsight which equipped late-model Mustangs and replaced the earlier N-9 gunsight, seen on the right. |

Armourers were also supposed to check out the gun-camera films brought back by "his" pilot to check wether the bullets were converging at the range requested by the pilot. Arming the aircraft with bombs meant that an arming wire had to be run from the bomb shackles to the cockpit, through the wing. Another responsability of the armourer was to take care of the gunsight. P-51B/Cs and early-style P-51Ds were equipped with basic N-3 or N-9 gunsights, which simply projected a light dot on a glass pane to indicate where the pilot was shooting. However, deflection shooting (shooting and turning at the same time) was far more complicated, and pilots had to estimate where to shoot, "leading" the bullets to the enemy aircraft. Later on, P-51Ds were equipped with K-14 gunsights, a British invention, which changed the position of the light dot to help the pilot in deflection shooting. These were considered as engineering marvels at the time, and greatly increased the P-51's lethality. Every armourer spent a week at an English base near Blackpool to learn about the K-14 gunsight. Apparently, the major problem was reminding pilots not to grab the gunsight when getting in or out of the aircraft.

Back from combat

But while the Mustangs were out, the mechanics had spare time. By the time the squadron was back, all mechanics were at their appointed hardstand. When the squadron came back in formation, it usually meant no combat had occured. But when the airplane came back in small groups, it generally meant action. The smoky gun muzzles would confirm the fact, and mechanics were to start looking for "their" airplane among the returning aircraft.

Once the pilot and plane had returned, the mechanics were then to complete post-flight inspection and repair any combat damage. They were also to attend to problems reported by the pilot. Armourers had to clean the guns and reload them, and then retrieve the gun camera film and put new film in. If any combat damage had to be repaired, it was usually done with a metal skin patch and rivets. Mostly these were bullet or flak holes.

When they were lucky, the mechanics would have the aircraft ready at nightfall.

This article was written by k51d. Any extra information or correction is welcome.

Advertising |